Barracuda Performance Products

Transforming Materials with Advanced Nanotechnology

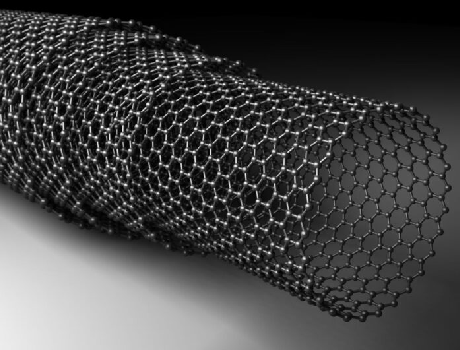

Pristine Graphene (PG) is a groundbreaking nanomaterial designed to enhance the strength, durability, and thermal performance of industrial applications. By leveraging graphene’s unique atomic properties, PG delivers unmatched performance improvements for materials exposed to high stress, temperature extremes, and environmental challenges.

What is Pristine Graphene?

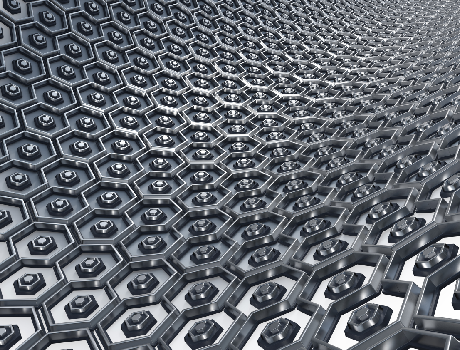

Graphene, derived from graphite, is a two-dimensional carbon allotrope with a honeycomb atomic structure. Pristine Graphene is a defect-free, high-purity form of this material, offering exceptional mechanical, thermal, and chemical properties. These attributes make PG an ideal additive for enhancing performance in materials such as UHMWPE, polymers, and industrial composites.

Key Benefits of PG

Extended Service Life

- Designed for continuous service at elevated temperatures, maintaining durability and structural integrity over time.

- Example Use Case : Industrial rollers operating at high speeds, lasting 8x longer than traditional materials.

Anti-Microbial Coatings

Protect surfaces from harmful pathogens with our anti-microbial coatings. Ideal for environments requiring high cleanliness standards, these coatings actively inhibit the growth of bacteria, viruses, and fungi.

- Applications: Industrial facilities, food processing plants, and Oil and Gas Storage Tanks.

- Benefits: Long-lasting protection, easy maintenance, and enhanced safety.

Thermal Stability

- Improves thermal conductivity to reduce heat retention and prevent overheating, ensuring consistent performance.

- Use Case : Easily formable to fit complex geometries, including curves and tailored designs.

Anti-Abrasion Coatings

Extend the life of your assets with advanced anti-corrosion technology. Designed to prevent rust and degradation, these coatings are essential for infrastructure exposed to harsh weather and chemical environments.

- Applications: Pipelines, storage tanks, offshore platforms, wind turbines, and other industrial machinery.

- Benefits: Reduced maintenance costs, improved asset lifespan, and increased reliability.

Enhanced Mechanical Strength

- Boosts tensile strength and modulus, enabling materials to withstand higher pressures and mechanical stress.

- Use Case :Pipes and infrastructure materials with improved resistance to deformation under load.

Improved Creep Resistance

- Resists deformation over time, ensuring materials maintain their shape and strength even under prolonged stress.

- Use Case :Structural applications exposed to high pressure or temperature.

Marine Anti-Fouling Coatings

Combat biofouling with coatings specifically designed for marine environments. These coatings reduce drag, enhance efficiency, and prevent the growth of algae and barnacles on submerged surfaces.

- Applications: Ship hulls, offshore platforms, and underwater structures.

- Benefits: Improved fuel efficiency, reduced maintenance, and longer service intervals.

Reduced Thermal Expansion

- Lowers the coefficient of thermal expansion, reducing warping and material failure in high-heat environments.

- Use Case :Industrial and automotive components requiring dimensional stability.

Greater Barrier Properties

- Protects materials against thermal and environmental degradation, enhancing longevity in harsh conditions.

- Use Case :Corrosion-resistant coatings and protective layers.

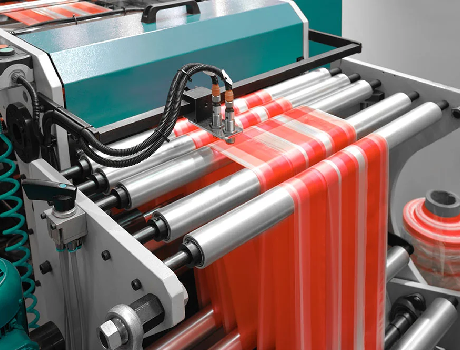

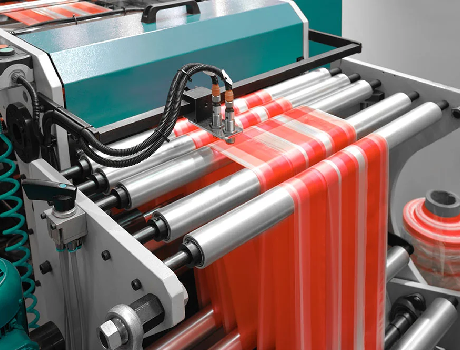

Case Study - PG Rollers in Conveyor Systems

PEGI is the material of choice for industries that demand lightweight, high-strength solutions

-

Challenge

Traditional UHMWPE rollers failed prematurely due to thermal expansion and limited heat dissipation during operation, causing noise, breakdowns, and downtime.

-

Solution

Rollers enhanced with Pristine Graphene were tested under identical conditions to assess performance improvements. The results were extraordinary. At 550 ft/min - PG rollers lasted 470 minutes without failure, compared to 35 minutes for standard UHMWPE. At 800 ft/min - PG rollers operated 3x longer than traditional rollers, with significantly improved thermal dissipation and dimensional stability.

-

Results

PG rollers maintained operational integrity at higher speeds and temperatures, improving service life and reliability. & Reduced downtime and maintenance costs, ensuring smoother operations for industrial clients.

Applications

Pristine Graphene is transforming industries with its versatility and performance

01

Industrial Components

Rollers, bearings, and gears with extended life and reduced thermal failure.

02

Infrastructure Materials

Pipes, coatings, and composites with enhanced strength and creep resistance.

03

Automotive and Aerospace

Lightweight, high-performance components for improved efficiency.

04

Protective Coatings

Thermal and environmental protection for industrial surfaces.

Proven Performance

Tested in real-world applications to deliver measurable benefits.

Sustainability

Reduces material failure, minimizing waste and improving operational efficiency.

Versatility

Adaptable to various industries and applications.

Why Choose Pristine Graphene?

Applications

PEGI is the material of choice for industries that demand lightweight, high-strength solutions

-

Defense

Body armor, helmets, and shields.

-

Automotive

Vehicle armor panels for lightweight protection.

-

Infrastructure

Walls, doors, and grid protection for secure buildings.

-

Aviation and Marine

Anti-icing and UV-resistant materials for extreme environments.

-

Manufacturing

Safeguarding equipment and reducing operational downtime.

Discover the Power of Pristine Graphene

Pristine Graphene is more than a material—it’s a transformative solution for industries seeking advanced performance, reliability, and sustainability.